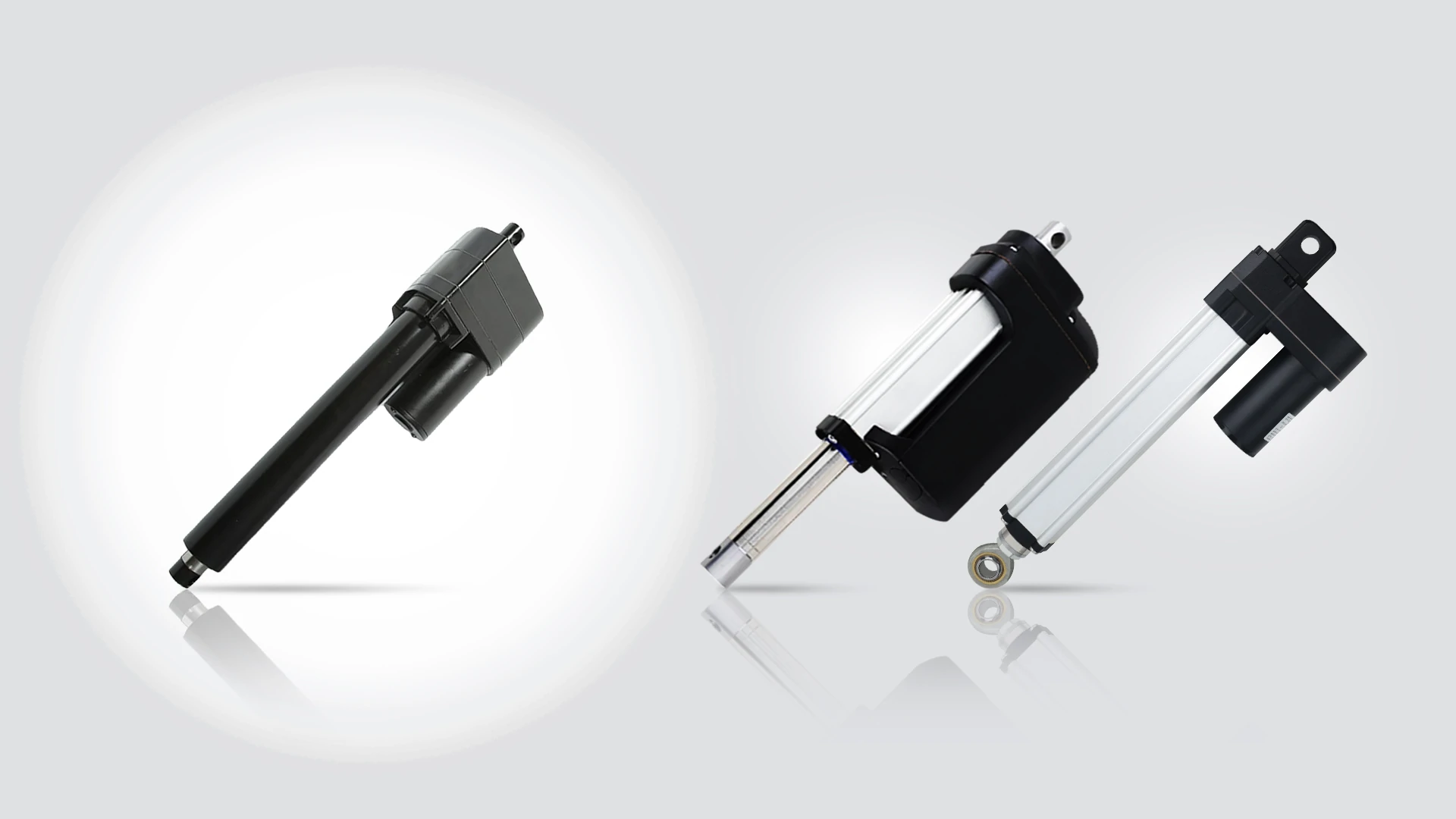

In the rapid development of industrial automation, Borman has become a leader in the industry with the outstanding performance and precise engineered solutions of its electric linear actuators. These actuators not only meet the strict requirements of industrial applications but also win the favor of enterprise-level automation systems with their reliability and customized services.

What are the technical advantages of Borman's electric linear actuators?

Rapid Deployment and High-Performance Integration

Borman’s electric linear actuators are renowned for their rapid deployment and high-performance electric actuator technology. These actuators are designed to meet the strict demands of industrial applications, offering robust performance with a maximum thrust of 7500 Newtons and a speed capability of up to 150 millimeters per second, while also supporting customizable stroke lengths to ensure flexibility and adaptability in various applications.

Why Our Actuator Motors Excel?

At Borman, our actuator motors are designed to surpass traditional expectations. Borman’s electric linear actuator motors are not just components; they are the heart of dynamic systems, driving machinery with a motion that ensures both strength and delicacy. The versatility of our rapid linear actuators allows for seamless integration across various industries, providing the necessary thrust and pull for complex operations. Our unique selling point lies in our proprietary quick response technology, which significantly reduces downtime and enhances productivity.

The Power Behind Precision

Energy Efficiency and High Performance: The Signature Features of Borman’s Design

Delve into the mechanics of our electric piston actuators and linear drives, and you’ll discover the core of our robust performance. Our range of power actuators, including the versatile 12V electric linear actuator and the powerful 12V DC linear actuator, are designed to meet the needs of complex and demanding applications. The signature Borman design is energy-efficient, ensuring that high speed does not equate to high power consumption, thereby optimizing operational costs without sacrificing torque or speed.

Designed for Industrial Excellence

Built for Harsh Environments

Borman’s inline linear actuators epitomize industrial strength and efficiency. These industrial linear actuators are capable of handling high-speed operations and are built for the rigors of heavy-duty tasks. The industrial actuators provided by Borman are more than just tools; they are reliable partners in the automation process, capable of enduring the toughest conditions without faltering.

Customization at Its Finest

Customized Design Services: Enhancing Operational Efficiency

Borman recognizes that every application is unique, and our ability to convert rotary motion into linear action with precision gear ratio is just the beginning. Borman’s control and stroke options are as diverse as the industries we serve, ensuring that each actuator is perfectly aligned with its intended function. Borman’s bespoke design service exemplifies our commitment to tailored solutions, offering a level of customization that elevates your operational efficiency to new heights.

Built to Last - The Borman Commitment

High Load Capacity and Heavy-Duty Construction

Quality is not just a buzzword at Borman; it is the foundation upon which every linear actuator is constructed. From high-grade materials to our meticulous assembly process, our actuators are designed to withstand the demands of any push and pull scenario. The high load capacity and heavy-duty build of Borman products guarantee a long service life, even under the most strenuous conditions.

Innovation in Motion

Precision Accuracy and Durability

Thanks to advanced lead screw designs, Borman’s actuators are at the forefront of motion technology, ensuring precise accuracy and durability. Whether powered by DC motors or AC systems, our actuators deliver the necessary force without compromising control. Borman’s exclusive rotational motion conversion technology stands as a testament to our innovative spirit and technical prowess.

Industrial Applications of Electric Linear Actuators

orman electric linear actuators play a pivotal role in industrial automation, providing efficient and precise motion control solutions. These actuators are widely used in manufacturing, automotive, and construction industries, among others. Known for their powerful force, smooth motion, and extensive control options, Borman electric linear actuators have become the preferred choice in industrial automation, ensuring reliable, accurate, and efficient motion control.

Applications in the Manufacturing Industry

In the manufacturing sector, Borman electric linear actuators offer essential motion control solutions to ensure the smooth and precise movement of machinery and equipment. They play a crucial role in industrial automation, allowing for customized motion to match specific manufacturing processes. Whether it’s precision measurement, assembly line operations, or robotic automation, Borman electric linear actuators provide the ideal solution. These actuators can generate high force output and handle heavy loads, making them suitable for a wide range of manufacturing applications.

The Role of Actuators in the Automotive Industry

In the automotive industry, Borman electric linear actuators play an essential role in providing linear motion control for various automotive machinery and equipment. Whether it’s the precise movement of robotic arms, automatic assembly line operations, or control of vehicle components, Borman electric linear actuators offer the necessary precision, control, and high force capabilities. With their smooth, reliable motion, and a wide range of control options, these actuators are the preferred solution for automotive applications where precision, speed, and reliability are critical.

The Importance of Actuators in the Construction Industry

In the construction industry, Borman electric linear actuators provide the necessary power and control for heavy machinery used in construction. They play a vital role in lifting, controlling movement, and ensuring the precise positioning of equipment. The Borman actuator product series includes options specifically designed to meet the heavy-duty demands of construction applications. Some of the main benefits of using Borman electric linear actuators in construction include:

- Reliable Heavy Lifting Capability: Ensuring the safe and effective operation of heavy construction equipment.

- Smooth, Precise Motion Control: Enhancing the precision and efficiency of construction operations.

- High Output Force for Heavy Loads: Suitable for various construction machinery and equipment.

- Abundant Custom Control Options: Meeting the needs of specific construction projects.

Borman electric linear actuators, with their exceptional performance, reliability, and customized services, have become the top choice for industrial automation solutions. We continue to innovate to ensure that our actuators can meet the challenges of future industrial automation while maintaining the highest efficiency and reliability. Choosing Borman means choosing a trustworthy partner to move towards the future of industrial automation together.

How to Choose the Right Electric Linear Actuator?

Key Factors to Consider

Selecting the appropriate electric linear actuator is crucial for ensuring optimal performance and efficiency in industrial applications. Here are several key factors to consider when choosing a Borman electric linear actuator:

- Stroke Length: Determine the required stroke length based on your application’s needs.

- High Force Capability: Choose an actuator that can provide sufficient force output to handle the load.

- Speed Requirements: Consider the speed capabilities that the actuator needs to achieve.

- IP Rating: Select the appropriate level of dust and water protection based on the application environment.

Understanding these key factors and considering the specific needs of your application can help you choose the most suitable actuator to meet your industrial automation requirements. If you’re unsure which actuator to choose, the Borman team can assist you in finding the best alternative to fit your needs.

Points to Note When Selecting an Actuator

When selecting an electric linear actuator, here are some important considerations:

- Stroke Length: Understand the stroke length required for your application and choose an actuator that can provide the necessary linear motion control.

- Control Options: Consider control options such as servo motors or control systems to customize motion.

- Product Range: Check the product range of the actuator to ensure you have a wide selection to perfectly match your industrial automation system.

- System Compatibility: Check the compatibility of system specifications with the actuator’s voltage and current ratings.

- 3D CAD Models: Borman provides 3D CAD models for your convenience, which can be found on our product pages.

- Bracket Considerations: Consider the necessary brackets for the safe installation and powering of the actuator system.

Factors Determining Actuator Speed and Force

The ideal actuator speed, force, and stroke length are important considerations for industrial applications. Here are some factors that affect these parameters:

- Electric, Pneumatic, and Hydraulic Options: Choose the suitable power type based on different applications.

- Push-Pull Load Capability: Ensure the actuator can handle the required push-pull loads.

- Pull Motion, High Speed, and Heavy Lifting: These are key requirements for industrial automation.

- Precise and Smooth Motion: Ensure efficient operation of machinery.

- Rotary Motion Control: Understand installation, wiring, and control options to optimize the speed and force of industrial automation.

These factors, along with the construction and ratings of the actuator, are the rules of thumb for choosing the right actuator for various industrial needs.

Borman electric linear actuators set a new benchmark in the field of industrial automation with their exceptional performance, precise control, and customized services. We continue to innovate to ensure that our actuators can meet the challenges of future industrial automation while maintaining the highest efficiency and reliability. Choosing Borman means choosing a trustworthy partner to move towards the future of industrial automation together.