Innovation

Home > Innovation

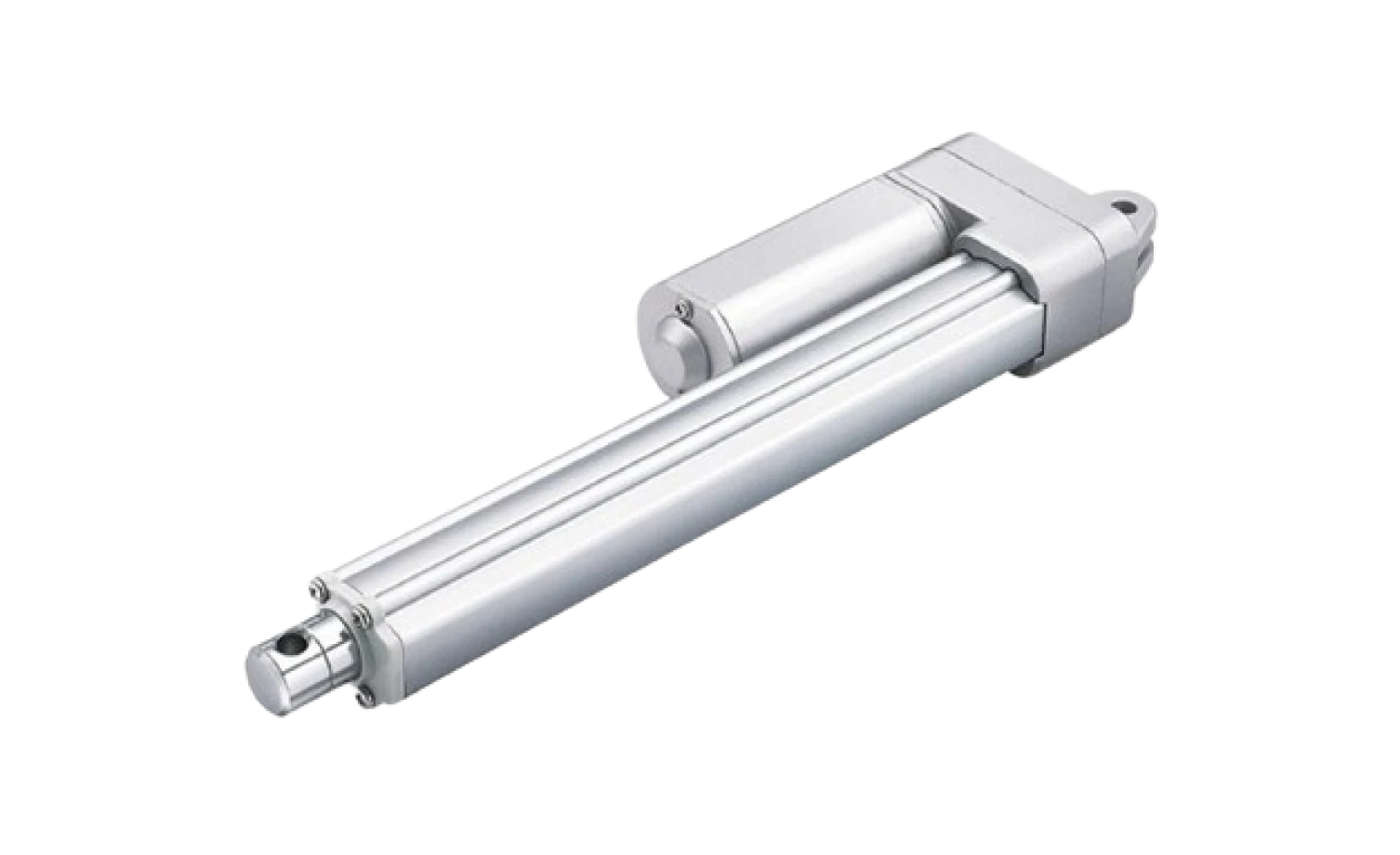

Revolutionizing Control Technology

Explore Borman Innovation Hub, where cutting-edge technology meets unparalleled functionality. Discover our advanced controllers designed to redefine industry standards, offering customizable features, exceptional performance, and seamless connectivity. Experience the future of control technology with Borman innovative solutions.

How Do We Innovate?

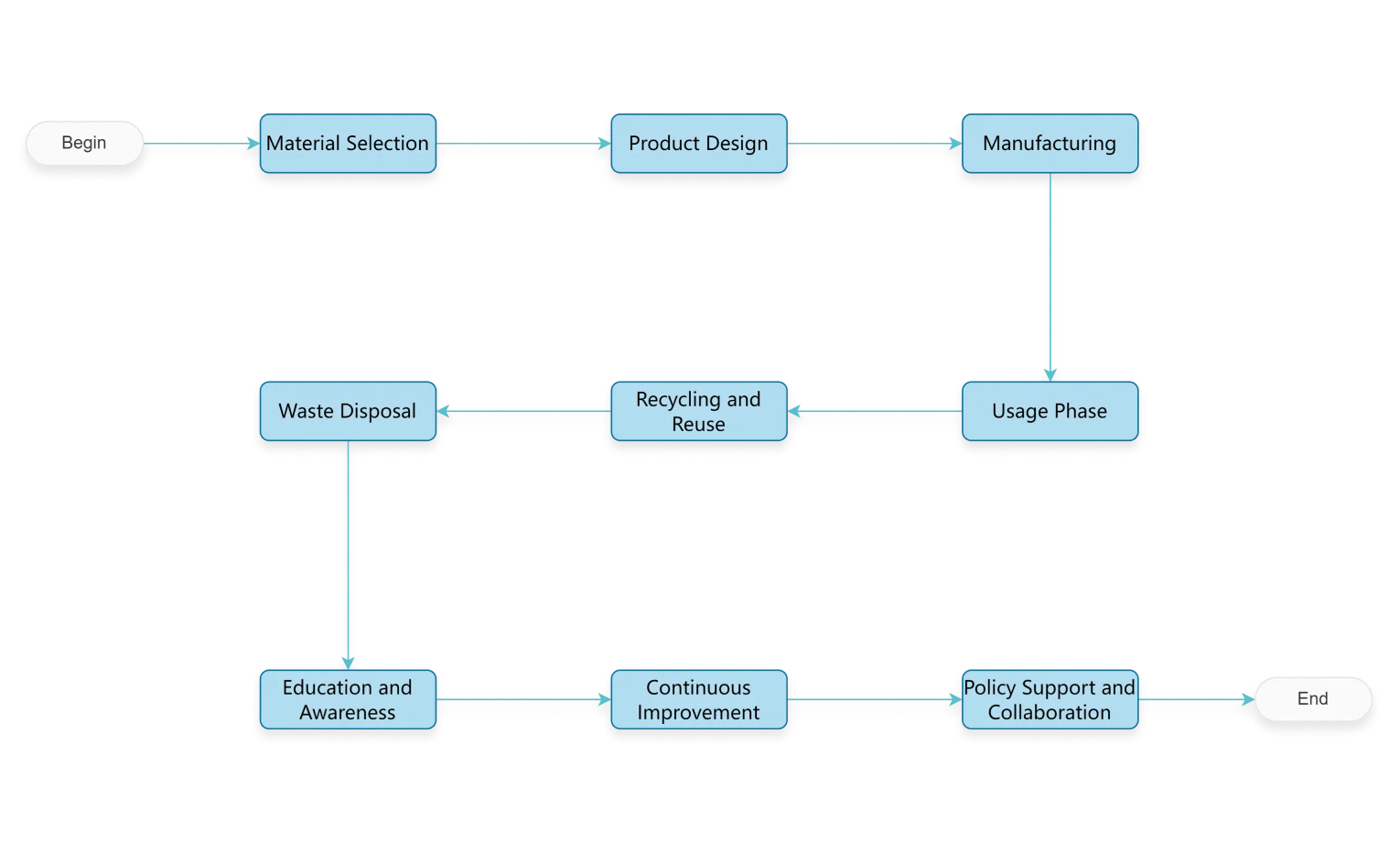

Energy-Efficient Linear Controllers

Develop linear controllers that operate with optimized energy efficiency. Employing advanced algorithms to minimize power consumption during standby and operation modes reflects a commitment to reducing the environmental footprint. By integrating smart sensors, these controllers can adapt their energy usage based on the load and motion requirements, leading to significant energy savings in the long term.

Recycled Material Usage

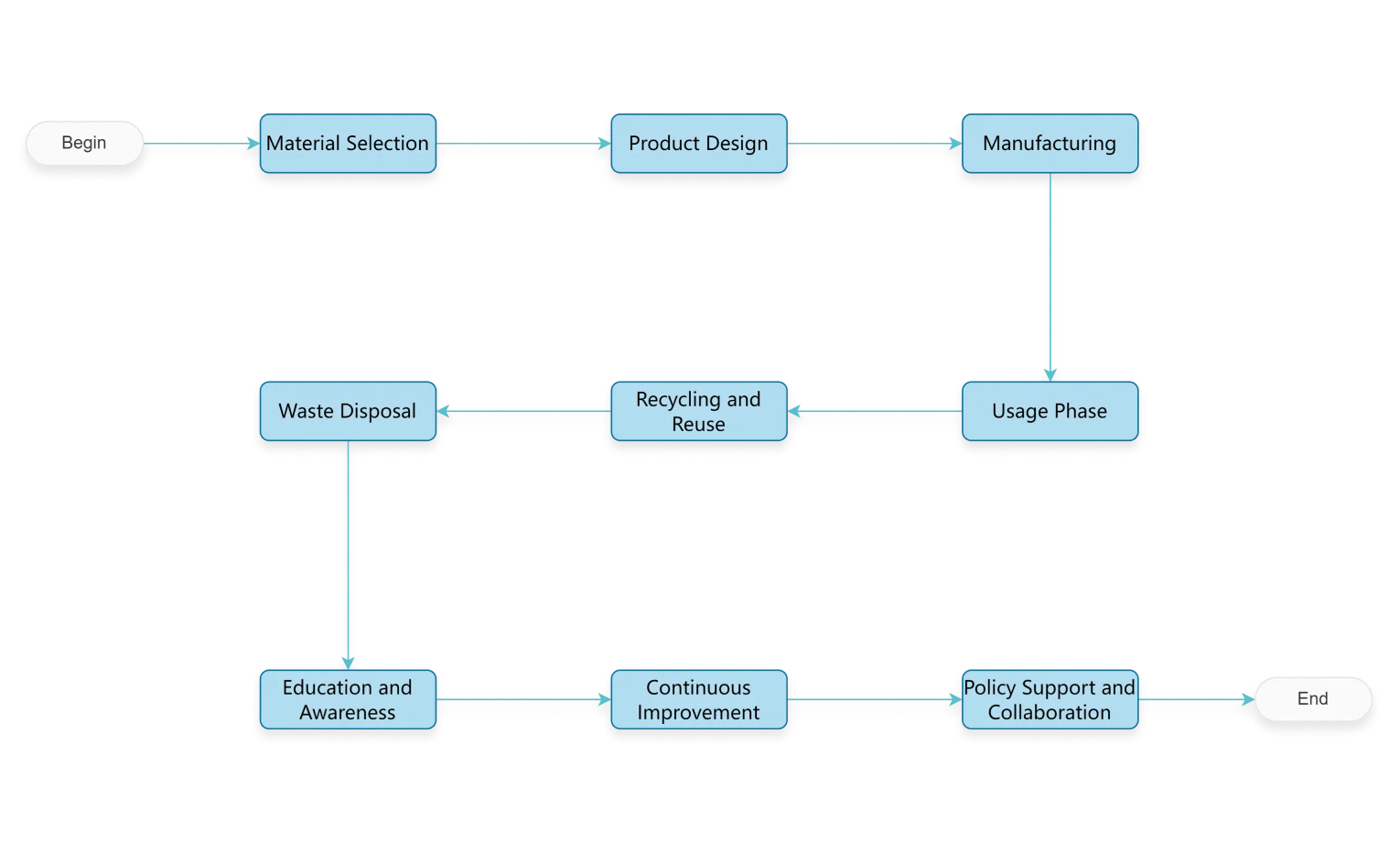

Emphasize the use of high-quality recycled materials in the manufacturing of your linear controllers. This not only demonstrates ecological responsibility but also shows innovation in material science. The use of such materials reduces waste and the demand for virgin resources, aligning with circular economy principles. Ensure that the performance of your controllers is uncompromised, thereby proving that sustainability can go hand-in-hand with technical excellence.

Recycled Material Usage

Emphasize the use of high-quality recycled materials in the manufacturing of your linear controllers. This not only demonstrates ecological responsibility but also shows innovation in material science. The use of such materials reduces waste and the demand for virgin resources, aligning with circular economy principles. Ensure that the performance of your controllers is uncompromised, thereby proving that sustainability can go hand-in-hand with technical excellence.

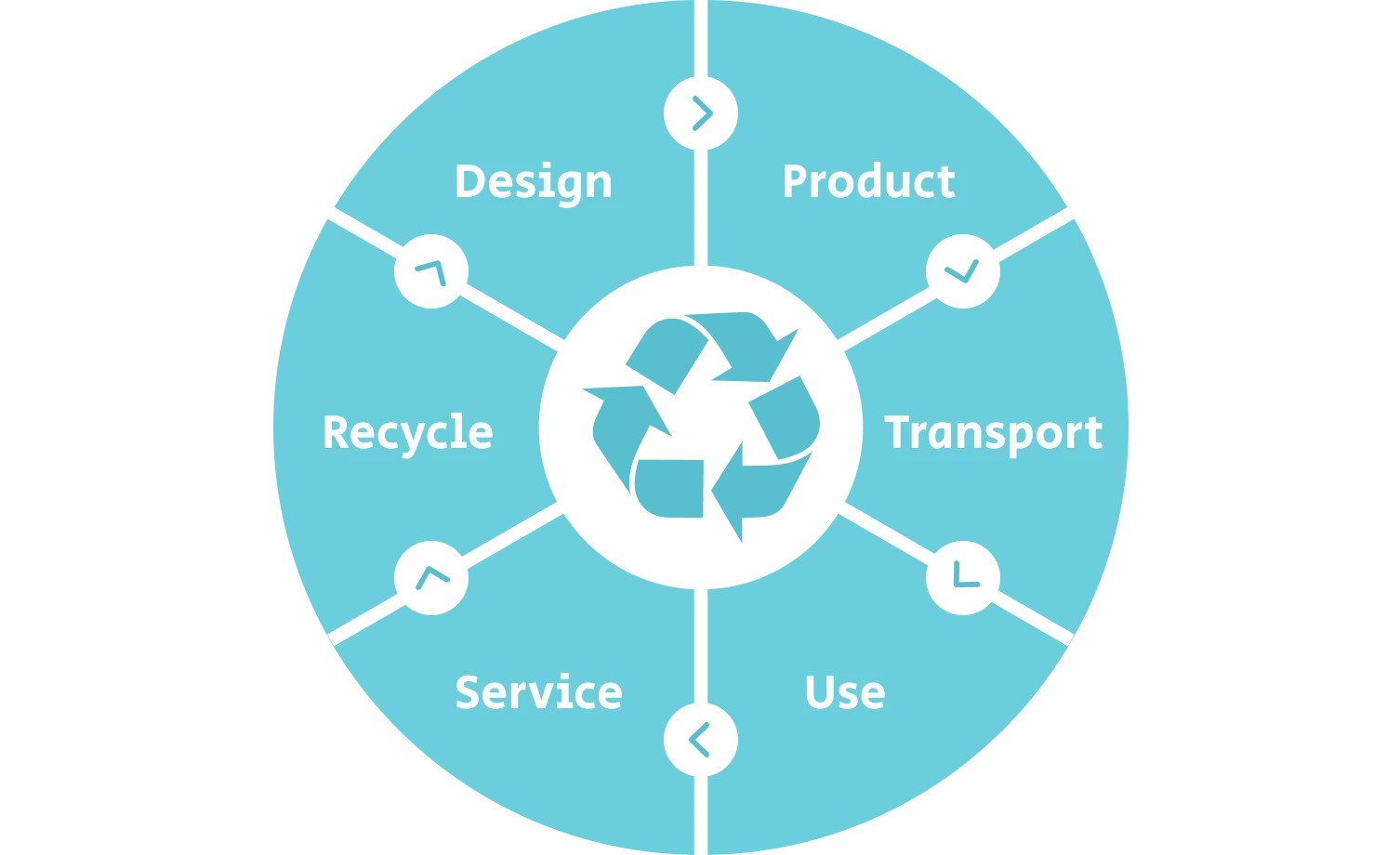

Lifecycle Management

Offer a comprehensive lifecycle management program for your products. This includes the ability to repair, refurbish, and recycle parts and controllers at the end of their life. By providing detailed documentation and services for each stage of the product’s life, you extend its usability and prevent unnecessary waste, highlighting your commitment to sustainability without sacrificing quality and performance.

Renewable Energy Integration

Design linear controllers that can easily integrate with systems powered by renewable energy sources such as solar or wind power. This forward-thinking approach not only broadens the application range of your products but also encourages the adoption of green energy within the industry. Your controllers could optimize energy use from these sources, maximizing efficiency and supporting the global transition to sustainable power.

Renewable Energy Integration

Design linear controllers that can easily integrate with systems powered by renewable energy sources such as solar or wind power. This forward-thinking approach not only broadens the application range of your products but also encourages the adoption of green energy within the industry. Your controllers could optimize energy use from these sources, maximizing efficiency and supporting the global transition to sustainable power.

Smart Control Systems

Create smart control systems that improve precision and reduce energy consumption through predictive maintenance and AI-driven efficiency optimization. These systems can predict when maintenance is required, preventing breakdowns and reducing downtime. Furthermore, by leveraging AI, they can continuously learn and improve, ensuring that the controllers operate at peak efficiency, thus saving energy and reducing operating costs over time.

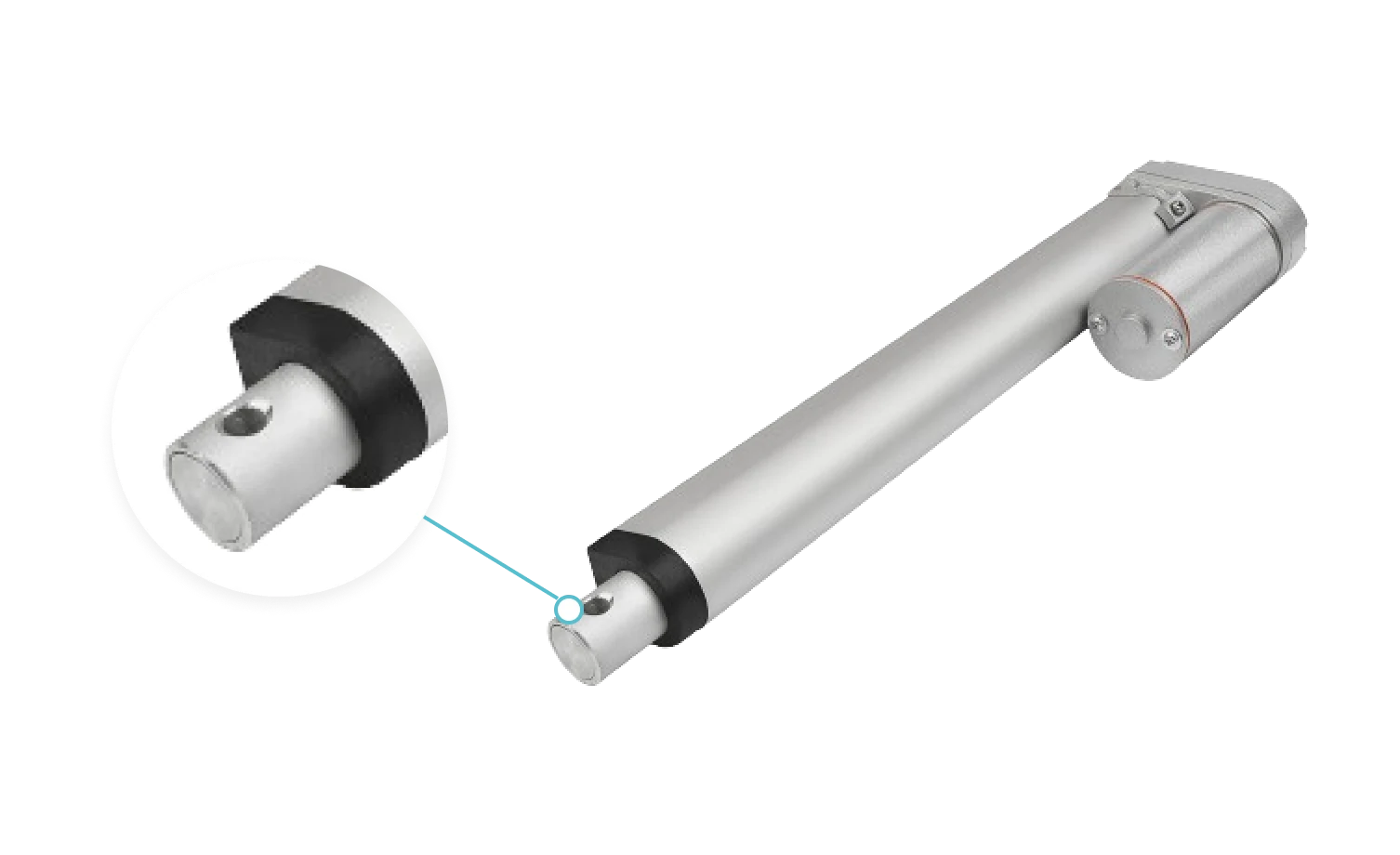

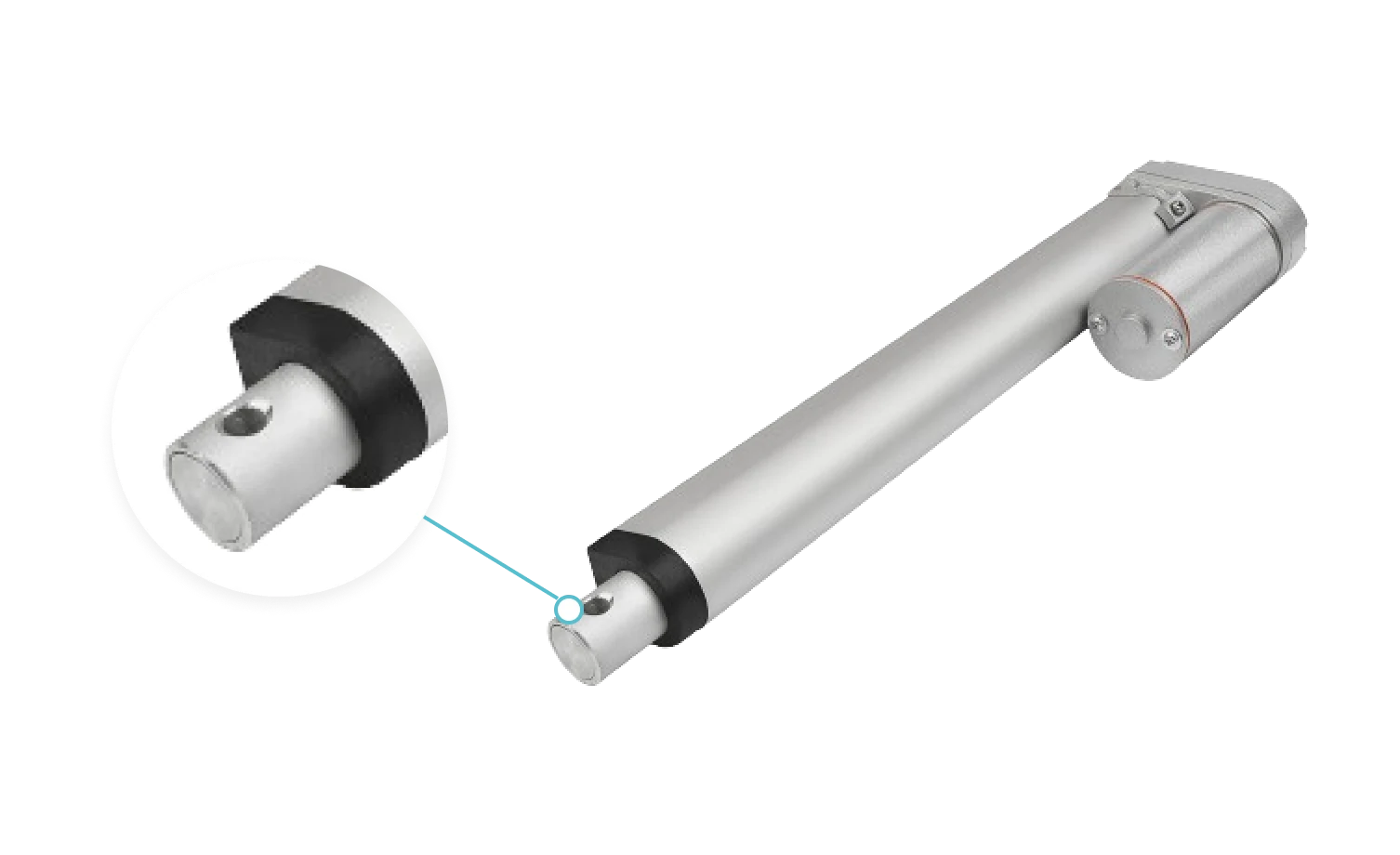

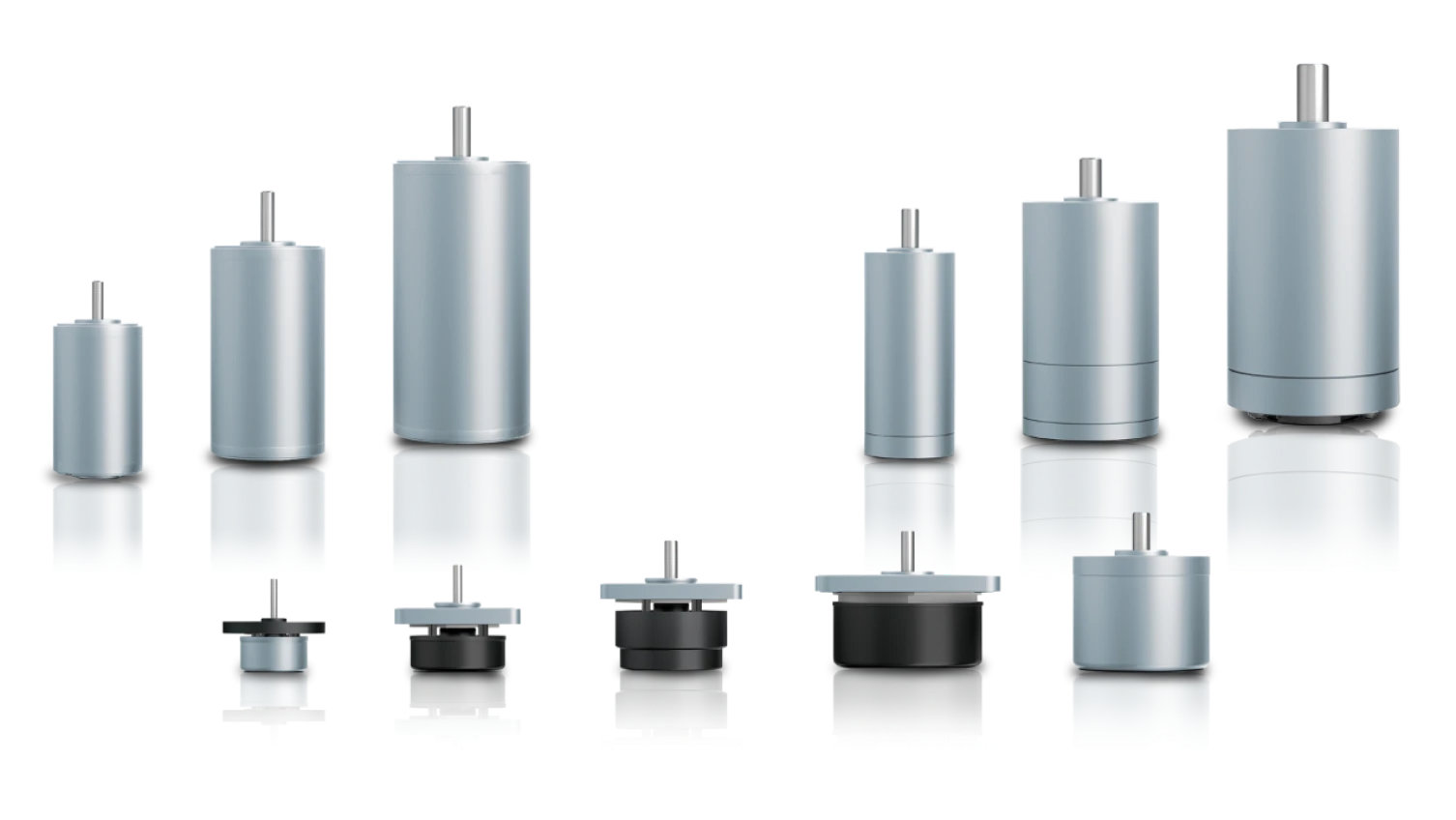

Low-Friction Component Engineering

To further enhance the sustainability of our linear controllers, we have innovated in low-friction component design. By utilizing advanced materials and coatings, we reduce the energy required to overcome frictional forces during operation. This not only decreases energy consumption but also minimizes wear and tear, extending the service life of our products. The precisely engineered components are optimized for smooth motion control, which is crucial for high-precision applications.

Low-Friction Component Engineering

To further enhance the sustainability of our linear controllers, we have innovated in low-friction component design. By utilizing advanced materials and coatings, we reduce the energy required to overcome frictional forces during operation. This not only decreases energy consumption but also minimizes wear and tear, extending the service life of our products. The precisely engineered components are optimized for smooth motion control, which is crucial for high-precision applications.

Smart Resource Management Software

Our linear controllers are equipped with Smart Resource Management Software (SRMS) that enables efficient resource utilization. The software provides real-time monitoring and control of power and material usage during the controller’s operation, ensuring optimal performance with minimal waste. The SRMS can integrate with existing enterprise resource planning systems to provide a holistic view of resource management across production facilities.

Renewable Material Lifecycle Program

We have initiated a Renewable Material Lifecycle Program (RMLP) to ensure that every component in our linear controllers is either recyclable or biodegradable. By adopting a cradle-to-cradle approach, we ensure that end-of-life components are repurposed in a manner that sustains the environment. This program is part of our commitment to reducing landfill waste and promoting the use of renewable materials in the manufacturing sector.

Renewable Material Lifecycle Program

We have initiated a Renewable Material Lifecycle Program (RMLP) to ensure that every component in our linear controllers is either recyclable or biodegradable. By adopting a cradle-to-cradle approach, we ensure that end-of-life components are repurposed in a manner that sustains the environment. This program is part of our commitment to reducing landfill waste and promoting the use of renewable materials in the manufacturing sector.

High-Efficiency Drive Systems

Our linear controllers feature High-Efficiency Drive Systems (HEDS) that significantly improve the conversion of electrical energy into mechanical motion. By using state-of-the-art motors and drive mechanisms, we achieve superior efficiency rates that surpass industry standards. HEDS technology not only reduces operational costs for our clients but also contributes to a lower carbon footprint for their automation processes.

Emissions Reduction Manufacturing Initiative

In line with our dedication to sustainability, we have launched an Emissions Reduction Manufacturing Initiative (ERMI) across our production facilities. This initiative includes the adoption of clean energy technologies, waste heat recovery systems, and stringent emissions controls. Our manufacturing processes are regularly audited for environmental impact, and we invest in continuous improvement programs to reduce our carbon footprint.

Emissions Reduction Manufacturing Initiative

In line with our dedication to sustainability, we have launched an Emissions Reduction Manufacturing Initiative (ERMI) across our production facilities. This initiative includes the adoption of clean energy technologies, waste heat recovery systems, and stringent emissions controls. Our manufacturing processes are regularly audited for environmental impact, and we invest in continuous improvement programs to reduce our carbon footprint.